Construction staplers are distinguished by the type of mechanism. Each of them has its own task.

Mechanical - for soft woods

They have a simple design. It turns out to work with such without skill. The models are lightweight, compact, allow working in uncomfortable positions. It is good if the body of a mechanical stapler is made of shockproof plastic, with a rubberized handle. And the lever is metal. Demolition will not be such a tool if handled wisely. When choosing a stapler, take a closer look at the type of percussion mechanism.

Torsion (coil) spring - for charging large forces. She does not shoot hard, but with a tangible recoil in the hand. With large volumes of work, this is discomfort.

Using the adjusting screw, you will ensure that the staples fit flush - they do not leave dents, do not spoil the material and do not protrude.

Leaf springs are used in professional models. It is easier to cocking and gives less recoil. You put in less effort to shoot, which means you don't get tired so quickly.

The discharge function allows the stapler arm to be folded down and fixed to the body. It is convenient for storage, transportation and insures against accidental shots. When this function is not available, the staples must be removed from the cassette.

If you plan to work with insulation, it crumbles. Gradually debris will clog the moving parts of the stapler. Be sure to use WD-40 (aerosol that prevents corrosion) or other lubricants. Spray into the guide part - where the staples are - and into the mechanism itself. This will prolong the life of the instrument. My cheap Chinese has already hammered thousands of staples, and it still works like a clock.

If you are not using the stapler for a long time, place it on the latch. Be sure to loosen the screw to the minimum position. This will relax the spring that is pressing against the staple driver. Thus, prolong the life of the instrument.

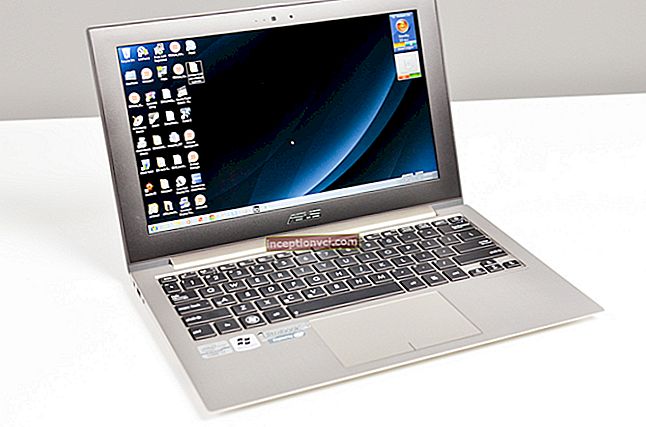

Electric - for large volumes of work

The motor is doing the hard work. The power of some models is up to 1.5 kW. They hammer the rig to a decent depth. Electric nailer (guns) work with staples, nails and pins. This expands their scope.

The principle of operation of an electric stapler differs from mechanics: the springs are bent by the drive.

- Press the button, → the spring is automatically bent, → the tool is ready for use again.

In terms of impact force and speed of work, it surpasses mechanical models.

A useful function is a double hit of a reusable shot - when an additional impulse is made on an unfinished bracket. In this case, the feed mechanism for consumables is disabled.

Pneumatic - runs on compressed air

They are sheathed with wood-paneled walls and ceilings. The pneumatics work under the force of compressed air (5-8 bar) supplied from the compressor. Fasteners up to 50 mm long fit into the wood like clockwork. Electrical and mechanical staplers cannot do this job.

Pneumatic staples have few moving parts and have a longer service life. The cost is less than electrical. But since it is necessary to connect a compressor, the price of a set of pneumatic tools increases significantly. And it's troublesome to transport.

To choose a pneumatic construction stapler, look at three parameters.

- Operating pressure the higher, the easier it is to drive long fasteners into dense material. For example, Makita AT1150A has a maximum pressure of 8.19 atm. It is capable of driving staples up to 370 mm long.

- Bending function for staples useful when holding two thin materials together and punching them through. You will need a metal anvil, which does not always come with the tool.

- Air hose Supplied complete with compressor. It does not exceed two meters. If you need a longer one, you will have to purchase it separately.

See the table for which construction stapler is better.

| Types of staplers | Purpose | Advantages and disadvantages |

| Mechanical |

|

|

| Electric |

|

|

| Pneumatic |

|

|

Construction stapler staples: dimensions

The most important detail for a stapler is the staples. Ideally, they should be of the same firm as the tool. Often on the handle and packaging, suitable dimensions are presented in the form of a diagram (thickness, length, width).

From my own experience, I note that staples from another company damage the striking plate. It flattens, burrs appear. Subsequently, even "native" staples will misfire. Be careful!

To choose the right tooling, look at the size and scope. Let's decide on the types of staples for the stapler.

| A type | Dimensions (edit) | Application |

| Type A |

| For upholstery and bonding of cardboard and fabric |

| Type E |

|

|

| ES type |

|

|

| Type B (thirty-five) |

| For corrugated board, bags and other types of packaging |

| Type Z |

|

|

| LM type |

|

|

| Type WM |

| For framing paintings |

Construction stapler: how to use

Using a stapler is elementary: press the tool nose to the workpiece and press the switch (handle if mechanical).

If the fixture is jammed or the staple is stuck, do the following.

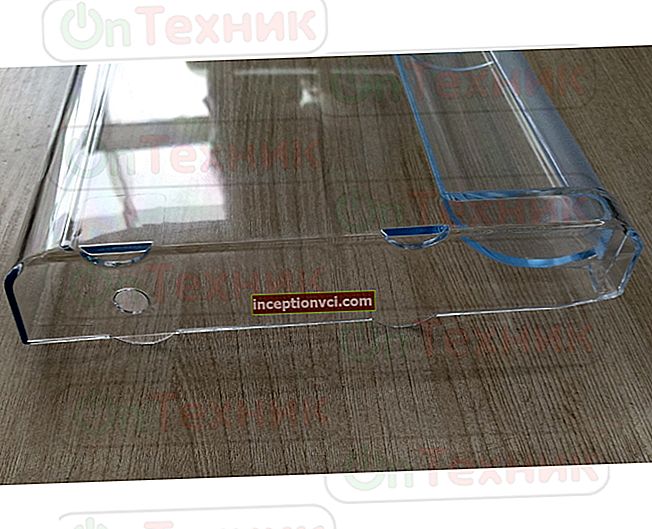

- Remove the staples first so they don't get in the way.

- Turn the tool upside down and find the two tabs on the plate. Grab them and slide them to the side.

- Unfold the stapler and remove the jammed staple.

- Replace the plate.

How to refill the stapler

- Remove the cassette and insert a set of staples.

- Close the cassette and lock until it clicks into place.

- Remove the lever from the lock.

Done!

Note: "Electric planer: how to choose and how to work with it correctly"

Watch the video how to insert staples into the stapler