Although we live in the age of ubiquitous use of synthetics, natural lumber is still one of the most popular in the field of home renovation and private construction. In order for the surface of beams, boards, parquet flooring, furniture boards and other wooden elements to become perfectly smooth, it must be properly processed. It is not at all necessary to plan the wood by hand. It is much wiser to use special electrical devices.

For the sake of fairness, it should be noted that quite often home craftsmen and professional builders also need the most ordinary, non-planed lumber. It is they who, as a rule, go to the manufacture of rough floors, rafter roofing systems, frame partitions, that is, all those wooden structures that will later be sheathed with finishing materials and are not visible. But the finishing, finishing of the interior requires the use of smooth products. Of course, you can buy bars, boards, furniture boards, lining and parquet planks already polished at the factory. But if you do the processing of these products yourself, you can save a decent amount of money and even enjoy a job well done. And it is quite possible to renew old wooden surfaces by cleaning off the peeling coating from them without the involvement of third-party specialists, provided that there is a good tool at hand.

Straight grinders

Makita GD060

These electrical devices are very convenient for cleaning small curvilinear elements: wooden fittings, moldings, mirror frames, furniture decor, narrow sills, window frames. Such machines got their name due to the following design features: their working heads are attached strictly perpendicular to the axis of the central shaft. Depending on the tasks being performed, the attachments can be changed. For rough grinding and removing layers of old decor, one-piece cylindrical and cone-shaped whetstones, as well as various metal brushes and circles, the sole of which is pasted over with a coarse-grained abrasive coating (skin), are excellent. The speed of rotation of the shaft can also be varied in accordance with the set goal: it is better to process soft carved wood at low speed, hard, without much decoration - at high speed.

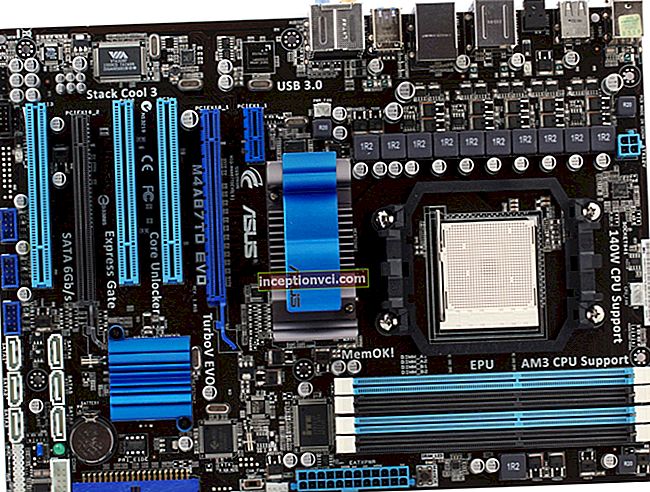

Grinders

Bosch GWS 850 CE

Their second name is angle grinders. They are real all-rounders, it is not for nothing that these tools are so popular with home craftsmen and professionals. They are convenient not only for grinding almost any surface, but also for sawing metal, concrete, ceramic and plastic parts. There is only one ban: you cannot cut wood with grinders! But it is possible and necessary to clean the edges of lumber and furniture parts, remove protruding burrs, smooth out chips and other defects, remove chamfers and level warped areas. The working part of the devices, on which removable disks are put on, is located at a slight angle to the longitudinal axis of the device, which greatly facilitates the work. Angle grinders are especially suitable for medium-sized workpieces. Curved and thin elements are easier to handle with convex ring-shaped (otherwise - petal) abrasive nozzles, and flat ones - with round discs without a hole in the center, attached to a special removable sole with Velcro.

Surface grinders

Black & Decker KA300

Wood flooring, countertops, door leaves, benches, lumber walls and other flat, scaled surfaces and large items with no particular relief are best and fastest cleaned with a surface grinder.The larger the amount of work to be done, the larger and more efficient the apparatus should be. If a coffee table, window sill or shelf can be sanded with a compact belt or vibration type device with an abrasive belt or a rectangular platform, then for scraping parquet or plank floors, clapboard walls and ceilings, it is much more correct to purchase or rent a special scraper with rotating working discs.

Work tips

Any sanding work is strongly recommended to be performed in protective plastic glasses (preferably ventilated, with small holes on the sides) and comfortable gloves that fit the hands well. When grinding and polishing small elements, clamping devices are indispensable. Before starting work, the product should be securely fixed between the vise jaws. Only then can you turn on the appliance and start finishing.

Universal tools

• Close relatives of grinders are small angle grinders with a working surface in the shape of an iron. Unlike classic models with round nozzles, they are able to saw wood and sand the most difficult-to-reach areas (corners, curved edges, joints between lining planks, etc.). Some types of these devices are equipped with a whole set of cutting, sawing, cleaning and polishing attachments. True, the power and productivity of the “ironing machines” are far from the highest. Although, in most cases, this cannot be called a disadvantage.

• Another versatile tool that can be used as a grinder is a conventional drill. You just need to fix a nozzle on it in the form of a rigid metal brush or an abrasive wheel.

Good to know

What you should pay attention to when choosing a machine for grinding wood:

• solidity of the manufacturing company (it is not worth buying the products of a one-day company);

• accuracy of fitting all parts of the product, absence of visible defects of the body and working parts;

• ergonomics of the device (it is extremely difficult to operate with an inconvenient tool, and the quality of work will be noticeably lower);

• availability of reliable protective elements (casing, vibration damping system, dust collection pipe, etc.).

Grinding machines are manufactured by many companies. The products of such well-known brands as AEG, Black & Decker, Bosch, Dremel, Makita, Skil, Metabo have proven themselves for a long time.